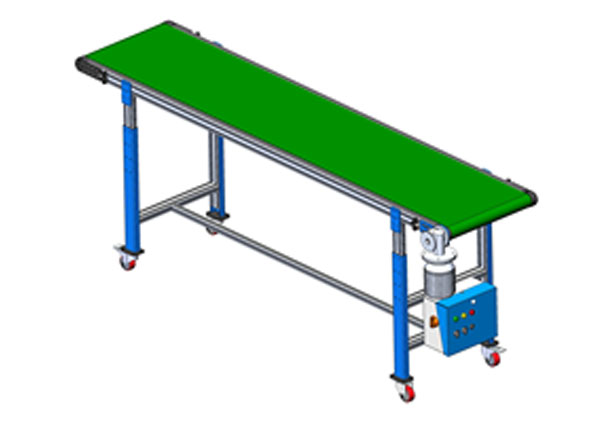

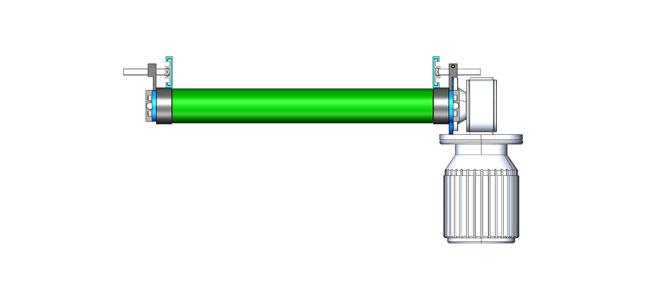

Standard Belt Conveyor

CFBC

Main Characteristics

-

Aluminium Extrusion 30X60 Profile

-

Bonfiglioli Gear Box.

-

0.25 Hp (.18Kw) Hindustan Motor Make 3 Phase Motor

-

Panel Box With Auto, Manual switch

-

Trip Indicator

-

Robot Interfacing

-

Driving & Driven Roller Dia 60 mm

-

Thk/Skf /Fag Bearing

-

Caster Wheel 2 Break 2 Free

-

PVC Belt 2 mm Thickness

-

Temperature : 10°C to +80°C

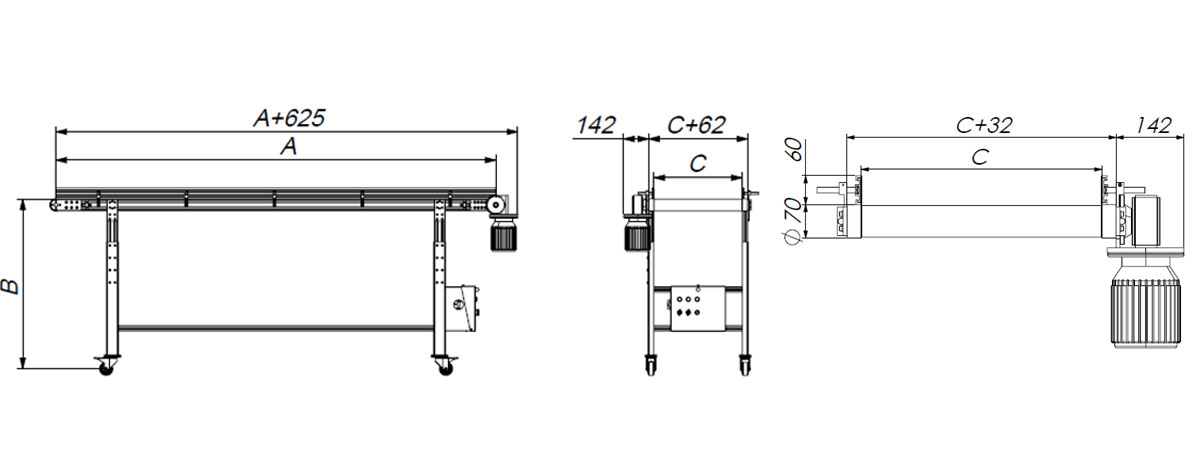

Drive Unit

-

Power

:1380 RPM (50Hz)

-

Voltage

:I/P 415 Volt AC O/P 415 Volt

-

Std installation

:on left-hand side with fixed drive

-

Gear ratio

:1:46

Standard Dimensional Features

Configurations

-

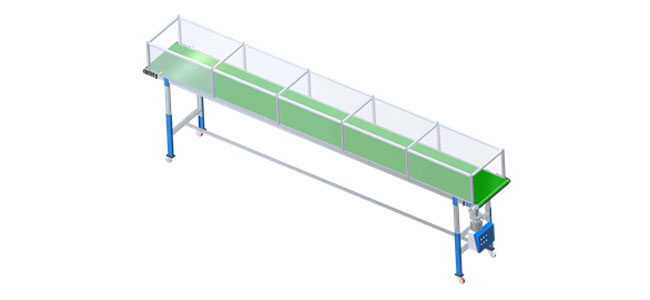

Use of sensors, PLCs, and vision systems for automated part separation.

-

Optimizing Speed control, and cycle time reduction.

-

Adjustable cavity spacing for different parts and product types.

-

Low power consumption and energy recovery.

-

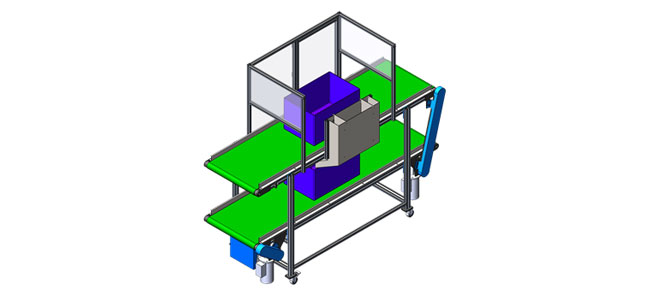

Acrylic panels are typically mounted on a frame that is attached to the sides or top of the conveyor system.

-

The frame is made from materials like aluminum, steel.

-

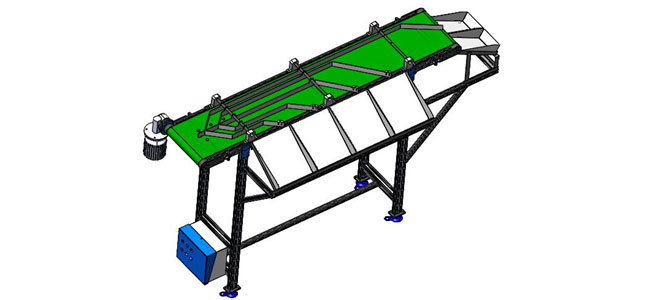

A double-decker belt conveyor is a type of conveyor system that consists of two levels for transporting items or goods.

-

This design allows for increased efficiency and space utilization compared to single-tier belt conveyors.

-

Its mainly used for cavity wise part separation.

-

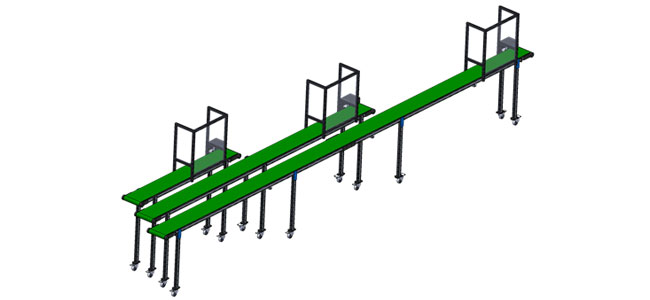

A 3-layer belt conveyor consists of three belts stacked on top of each other, typically used in material handling systems to increase capacity and efficiency.

-

These conveyors are common in industries like manufacturing, and logistics, especially for handling bulk materials or in high-volume production environments.

Side Containment Panels

-

Side Guard Height (Standard)- 50mm

-

Side Guard Adjustment- 0 mm to 50mm

-

Available in- SS, Acrylic, MS, Nylon

-

Corrugated Side Wall

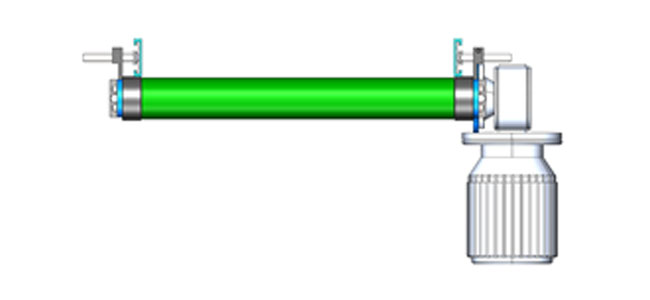

HEAD ROLLERS

-

Head Roller Diameter- Dia 60

DRIVE UNITS

Roller Dia-60

-

Gear Ratio

:Belt Travel Distance

-

1:46

:6 Mtr/ Min

-

1:10

:25 Mtr/ Min

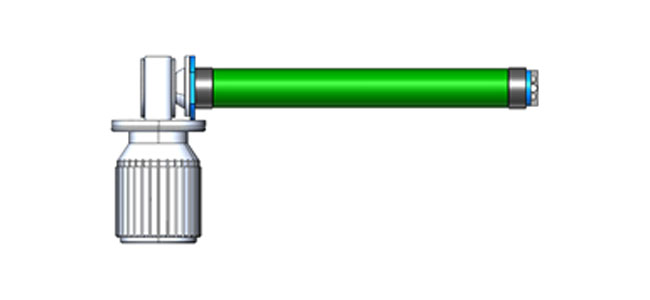

Roller Dia-40

-

Gear Ratio

:Belt Travel Distance

-

1:46

:10 Mtr/ Min

-

1:10

:17 Mtr/ Min