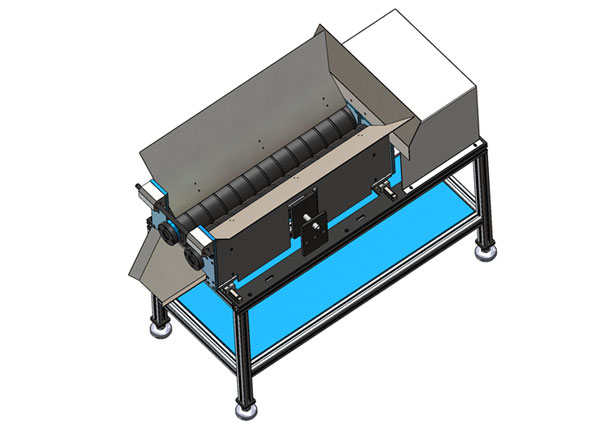

Independent Separator With Double Roller

CPRS

-

A part runner separator is a device used in manufacturing (mainly injection molding) to separate finished parts from runners.

-

It works by using rotating drums mechanisms to distinguish and sort the parts efficiently. This improves automation, reduces manual labor, and enhances production speed

-

Increased Automation: Reduces manual labor for separation.

-

Better Material Handling: Ensures efficient reuse of scrap materials.

-

Improved Productivity: Speeds up the production process with minimal downtime.

-

Enhanced Quality Control: Reduces defects by ensuring proper separation of parts and runners.

-

Overall Impact: Increases efficiency, reduces waste, and boosts production consistency.